Challenges and Opportunities for Circularity in Textiles

by Kristin Schillings

In the US alone, textile waste is an 11+ million ton problem annually.

In addition to what the cities and counties collect in landfills, a LOT of used clothing is exported.

Fabric from millions of homes and closets end up thousands of miles away, creating significant waste and pollution overseas.

In this post, we look at the world of textile “recycling” and the opportunities that a circular approach offers, including steps you can take today towards reducing textile waste.

Let’s start with a quick stop at the manufacturing plant. Significant amounts of Pre-Consumer (Post-Industrial) Waste come from manufacturing processes, with producers throwing away a lot of stuff, from scrap fabric to finished goods.

Remember Burbury literally burning over 30 million dollars worth of overstock?

The stuff that comes out of our closets is Post-Consumer Waste, or textiles somebody has bought and no longer wants. This is mostly clothes, but also includes household textiles like towels, sheets, bedding, etc.

Of the millions of pounds of textile waste disposed of at municipal centers yearly, less than a quarter is recycled. Most cities do NOT have curbside textile recycling. If you put your unwanted clothing in your curbside recycling bins, it contaminates the recycling stream and can lead to costly shutdowns of processing lines.

Textile collectors are private companies that collect post-consumer textile waste.

You have probably seen their collection bins at shopping centers and local businesses.

In addition, many cities (including the ones in Wake County, Durham County & Orange County) contract with Textile Collectors and host collection bins at their convenience centers.

These collections of unwanted household textiles are called credentialed clothing. It’s a commodity, sold in bulk to Graders. Graders sort through credentialed clothing and separate it out by quality, or grade.

Bales ready to be shipped to a Grader

About half of what graders go through is reused as clothing. Some of this is sold to thrift stores domestically, but there are more textiles collected than could be used in the US alone. In fact, many thrift stores end up using a textile collector when donations overflow.

The rest is cut into wipers or turned into shoddy - shredded fiber used in things like insulation and toys. The remaining product of this process will eventually be thrown away. Unfortunately, there is no infrastructure to recapture these materials downstream.

The Problem with Textile Recycling

Recycling always sounds nice! Unfortunately, as we’ve learned with plastics, an overwhelmed recycling system has negative consequences.

In reality, textile recycling relies heavily on “downcycling”. The fibers lose value as they go through the process, and eventually have no option but to be landfilled.

For example, a t-shirt sold second-hand eventually ends up full of holes and is recycled. Insulation made from its shredded fibers is eventually thrown away.

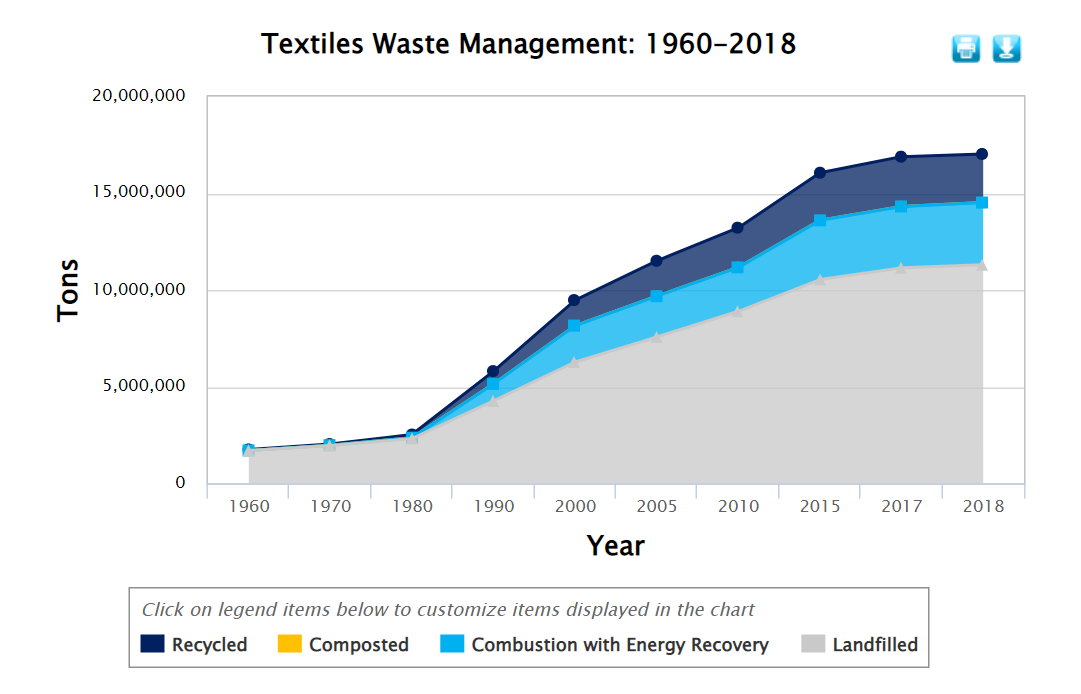

The increasing quantity of textile waste is another significant challenge to recycling systems, as evidenced by exponentially increasing quantities of material ending up in municipal solid waste since 1960.

The existing recycling infrastructure can’t keep up.

The 5 million pounds the EPA estimates is recycled annually in the US is based on what municipalities capture at their centers. This isn’t the whole picture. Textile collectors are picking up from all over the place, with the US being he largest exporter of used clothing in the world.

Over $600 Million dollars worth of used clothing was exported from the US in 2020 alone.

A lot of the secondhand clothing exported ends up creating environmental hazards in the countries they end up in, and concern about restricting the viability of local textile manufacturing in those economies.

The Circular Opportunity

With the exponentially increasing amounts of waste, environmentally expensive manufacturing, and insufficient recycling streams, textile waste is a powerful example of why we need to move towards circularity.

At the most optimistic, your t-shirt will be reworn until it falls apart. You’ll stick it into a textile collector’s bin, and it’ll end up as shred. They sell it to somebody who makes dog beds, and it gets to stick around for another couple years until it stinks too badly to do anything but throw it in the trash.

Now multiply this scenario exponentially. Remember, just what the municipal centers capture is in the millions of tons annually. The capabilities of our existing recycling streams are completely overwhelmed. Downcycling can’t be the only answer.

We must find ways to move to circularity - to maintain the value of fibers throughout their life cycle, and to have a plan for textiles to return to a raw material when they can no longer be used.

Fortunately, driven by consumers increasingly concerned about the environmental impacts of the fashion industry, there are a lot of people in the industry working on circular solutions.

What can we do as citizens and consumers?

Buy used clothing from local thrift shops and/or online used clothing sites like Thredup and Swap.

DO NOT put textiles in your recycling bin with plastic, paper and glass recycling.

Explore options to keep textiles in use:

Host a clothing swap

Get inspired by clothing upcycling ideas on Pinterest

Check out Towards Zero Waste’s online sewing meetup or help Don’t Waste Durham make reusable bags!

Learn more about the growing sustainable fashion movement and join Redress Raleigh’s movement for responsible fashion

Ask your favorite brands to start take back programs if they do not yet exist, or what they are doing to eliminate textile waste and move towards a circular model.

Advocate for EPR or extended producer responsibility laws for the textile industry.

How is the industry moving forward?

Manufacturers taking responsibility for their product’s end of life is critical to circularity. Regulatory systems enforcing reasonable requirements is one way the industry can be incentivized. We need them to manufacture in ways that leave the fiber in used product something that can be spun back into yarn. For example, the European Commission is moving towards extended producer responsibility in the textile industry.

Despite significant cost challenges in an industry that relies heavily on manual labor, many in the industry are working on more efficient ways to turn existing textile waste back into yarn. Accelerating Circularity is running pilot programs to turn pre and post consumer waste into usable yarn and get it to manufacturers. Lots of new technology is emerging, as automated sorting of colors and fiber types is a key piece of making a closed loop system possible.

Some upcycling designers, small brands, and artists are starting to look to textile waste streams for their supply. Though difficult to scale up, this is a great way to provide consumers with better options.

Domestic second hand clothing markets, an important way to keep material in circulation, are growing rapidly - particularly online.

Is it a terrifying large problem? Yes, certainly. The quantities involved here are overwhelming. We’re fighting cultural forces and huge systems of infrastructure that have been the way they are for a long time.

That said, big change is coming. As awareness spreads, regulations change, and industry players invest in better options, we will have new, more sustainable options for textile recycling in the coming years. How fast things move is up to all of us.